Volume Two

Modern States

Industrial Revolution

Beginnings

The British Industrial Revolution began in the fifteenth century with enclosures of common land for sheep farming, which afforded some welcome money from taxes to a government debasing the coinage. Poor laws followed, to cope with the dispossessed 'surly beggars' threatening order in the countryside and the settled life of towns, though both town and countryside grew richer as a result of land improvement. Contemporary with these social changes came a proto-Industrial Revolution where craft skills were learnt from the more advanced European countries and their machines copied. So appeared blast furnaces, tin mines, paper mills, powder mills, canon foundries, glass works, sugar refineries, and many such home-grown industries that absorbed some of the dispossessed labour. Such industrialisation slowed after 1640, however, and agriculture resumed its dominance. More labour was shed in the 18th century as farms became larger and land was enclosed in large estates, particularly under the 1760-1870 parliamentary enclosures, where one sixth the area of England was enclosed under some 4,000 acts of parliament. Materially, many aspects of English life improved, but whole classes of workers were thrown into poverty as their small-holdings and livelihoods disappeared. Workhouses were instituted to provide relief, and the Corn Laws repealed to let in cheap wheat from the American prairies. Long hours in the mills and factories became the norm as the new poor found employment in the rapidly expanding towns, first in the large textile mills driven by waterpower, and then in factories powered by steam engines that employed locally-available coal and iron ore. {1}

World Trade

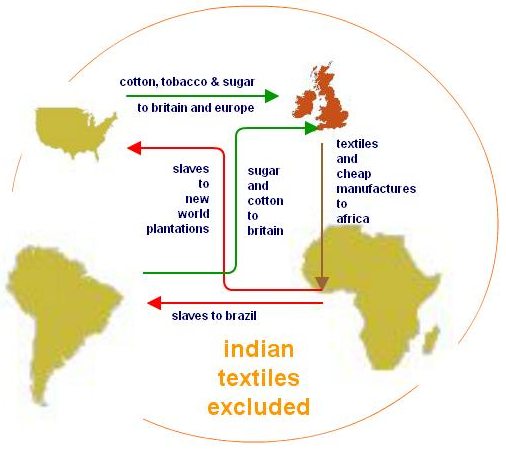

To protect its cottage industries, Britain first banned Indian textiles, and then, under mercantile-orientated governments enshrining industry and property rights, employed waterpower to run large cotton mills. The first machines were rudimentary, but benefited from continual improvements and inventions: Goods were initially transferred by canals, but pithead pumps and steam engines quickly developed into cheaper railway transport. {2}

Conditions were grim indeed in the tobacco, sugar and cotton plantations, and in the precious metal mines of the New World that formed an essential part of this trading model. Britain received tobacco, sugar and cotton from slave plantations in Brazil, the American colonies and the Caribbean. The cotton it wove into cheap textiles, which were exported to clothe plantation workers, and help buy slaves from Africa. The slaves were transported to Britain, and thence to plantations, and to mines in Latin America. {3}

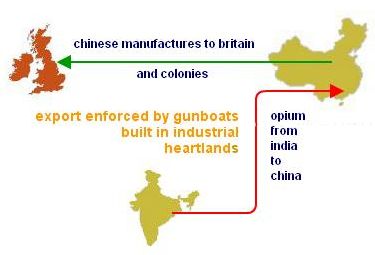

The silver obtained in return from Potosi and the Mexican operations was used to purchase tea, china and silks from China, these being sold to merchants in Britain, Europe and the American colonies. When Chinese demand a century later threatened to empty British banks of silver, the British East India Company promoted the sale of Indian opium to China, overcoming local resistance by wars, which eventually opened up the country to British (and other European) manufactures. The Chinese had no answer to steel-built gunboats that were the products of Industrial Revolution, any more than had the Japanese confronted with Perry's fleet in 1853. {4}

Contemporary historians have generally disliked this Williams model, noting that slave trafficking contributed to less than 5% of British trade revenues. But who profited from the trafficking is less important than the undoubted importance of plantation products, which were created by labour without the need of sustenance in England: a type of 'manpower at a distance' that was gradually taken over by water power and then coal-fired steam engines. Equally important — indeed more so, given that millennia of slavery had not led to an industrial revolution before — was the growth of enterprise in Britain, a change in mentality, from landed wealth, conspicuous consumption and/or regal display to investment, innovation and respectability. Britain had natural resources in coal and iron ore, and scientific experiment was encouraged. The government created a national market by abolishing internal tariffs, investing in transportation, erecting an external tariff to protect fledgling industries, creating banks to stabilize the currency and mobilize domestic savings for investment, allowing land, natural resources and labour to be treated as commodities, promoting religious freedom and finally undertaking mass education to prepare people for industrial work. Land was protected by title, and joint-stock companies restricted investors' liabilities to the shares purchased. The profits made by enterprise did not encourage population increases in Britain because the profits were not shared but kept within hardworking business families, who commonly purchased land and joined the gentry class. {5}

Why Britain?

The Industrial Revolution may have begun in England because abundant coal tipped the balance against other western countries. Coal, and such cheap fuel sources were not available to Ming China, though conditions were otherwise propitious. But the root reason was the ratio of wages to the cost of capital. Whatever the individual injustices, land improvements under the enclosures acts and the flourishing overseas trade, had created a comparatively well-paid working class, several times higher than subsistence. Banking was well established. British wages were therefore high relative to the cost of capital, higher than the case in other European countries, and markedly more than in China or India. Coal in fact gave mills and factories the cheapest energy in the world. Cotton textiles grew from an insignificant addition to British GDP in the mid-eighteenth century to be its largest, accounting for 8% in 1830 and 16% of manufacturing jobs. (Even more important was cotton's role in the USA economy.) Technical improvements drove down the price of fabrics until they undercut the vast but handicraft textile producers of India, forcing workers back into agriculture. In England, when cottage weavers could not compete with cotton mills, their recourse was to mill and factory employment, as the workhouses instituted by the new Poor Laws made charity an unattractive option. {6}

Other Countries

The Industrial Revolution soon spread to other countries. France was spinning 54,000 tons of cotton a year by 1840, far less than Britain's 194,000 tons/year, but still appreciable and made possible by further-improved mill technology. Germany was still only 11,000 tons/year, but heavy industry soon caught up and exceeded Britain in many respects, through R&D and banking capital, supplied long term at low rates for Board representation. In 1880 Britain produced 23% of the world's manufactures, against 18% by France, Germany and Belgium combined. By 1913, however, the ratios had shifted, to 14% and 23% respectively. {7}

That ratio of wages to the cost of capital was still important, however. It made no sense to introduce industrialisation into low-wage countries. A jute and cotton industry did flourish in Bombay, however, and was processing 360,000 tons of raw cotton in 1913, but the industry made only a small impact on so large a country, employing well under 1% of the labour force.{7}

Matters were again different in north America. Canada was a 'staples' economy, supplying cod, furs and timber to Europe in exchange for manufactures. Pennsylvania exported wheat. The southern states exported rice, and the Caribbean sugar, generally using slave labour. Mexico and the Andean countries produced silver, under appalling conditions but employing only a small percentage of their labour forces. It was in the prosperous northern states, where wages were comparatively high (twice Britain's in 1830), that industrialization took place, again with cotton that was grown across the US south to supply Britain's industrial needs. Eli Whitney had invented the cotton gin in 1793, and Francis Cabot Lowell built an integrated spinning and power weaving mill in 1831. Oliver Evans built an automatic flour mill, and American government arsenals were making interchangeable parts for muskets in the 1820s, laying the foundations for the automated assembly line that was important the following century, in automobiles and armaments especially. {7}

Japan

Different again was Japan, which employed the 'great leap forward' or 'big push’ industrialization process at a strategic stage, as did Russia and then China. The Japanese story falls into four parts. The Tokugawa (1603-1868) period restricted trade but created communities tightly knit by social custom. Industrialisation began under the Meiji period (1868-1905) where sweeping reforms paid off the samurai, and feudal domains were surrendered to the crown. The four classes of society were abolished, allowing anyone to take a job, and the western 24-hour clock was introduced. New varieties of wheat were planted, and irrigation improved for other crops. Education was encouraged, and promising students were sent to study abroad, bringing back technical knowledge and ideas. Large factories were built, but modified to take advantage of cheap labour costs: double shifts were introduced and parts often constructed of local materials. The banking system was chaotic, and stayed so for fifty years, but the funding gap was closed by venture capital. The most important development of the Imperial period (1905-40) was the direct intervention of the state through institutions like the Ministries of the Interior and Industry, which brought in foreign experts for short periods, trained up engineers, and ensured that metallurgical, engineering and chemical industries were funded by state concerns. The Japanese were encouraged to save, and these close-knit associations of finance, state and industry (kaibatsu) protected Japan from outside competition. GDP per capita rose from $737 in 1870 to $2,874 in 1940. The final period, when Japan recovered from WWII, is termed the 'big push', when all components of an advanced economy — steel mills, power plants, vehicle factories and whole cities — were constructed simultaneously, ahead of supply and demand. Capital investment reached a third of the national income in the 1970s and, helped by trading agreements with America and Europe, GDP per capital averaged 5.9% between 1950 and 1990, touching 8% in the 1953-73 period. Despite the rise in wages, Japan became the world's cheapest steel producer, and its automobiles out-designed and out-priced models in America and Europe. {7}